Mr. Amin Degani

Dr Degani has been a Professor at Harvey Mudd College & Cal Poly, California. He pursued his Doctor of Philosophy [Ph.D.] (Material Science) from Mellon University, Pittsburgh, U.S.A, Masters of Science (Process & Extractive Metallurgy), Carnegie Institute of Technology, Pittsburgh, U.S.A and Bachelors Of Engineering (Metallurgy) From Poona University. He also completed his Post Doctoral Fellow at University of Southern California, Los Angeles. A dynamic professional with over 50 years of rich extensive experience in the field of Steel, Melting Rolling Ferro Alloys, After returning from the U.S, started in Metallurgical plants with Mukand, Piramal Steels,Tarapore: and consulting work with Special Steel, Tarapore, Panchmahal Steel,Kalol, Singh Steel, Tarapore; Dandeli Ferro Alloys, Karnataka, Aslo Steels Ltd, Gujarat; R B Jodhamal Jammu: First EPC plant SaiBaba Casting, Sinnar:then Anik Steel, S.R.M. Steel (P) Ltd, Shree Electromelt, Bhavnagar: Viraj Alloys Limited, Tarapur:VedikIspat , Hindupur:Liberty Steel, in Khartoum, Sudan: Western Steel & Forgings Limited, Tema, Ghanato name a few. Universal Mining & Chemicals In Zambia, is 400 Crore plant established with a capacity of 2,00,000 tons / annum to produce TMT Bars, Wire Rod Coils, and sections. Dr. Deganifirst brought the concept of secondary refining using the convertor from Germany in 1984. At Peekay Steels, steel is processed through the CONVERTOR, to achieve lowimpurity levels (sulphur

<0.004% & phosphorus <0.004%) and controlled gases like Oxygen, Nitrogen & Hydrogen. All grades of special steels from Carbon Steels to Stainless Steel, Duplexing and Triplexing, High Alloy Grades as well as other Special Grades are made for Valve Bodies, Gear Box and Pump casings. Today Peekay Steels is declared as the best Foundry in the World.

Mr. Sunil Sarwade

SUNIL SARWADE is the PROPRIETOR of SIDDHI TECH a CORE INDUSTRIAL TASKS FORCE, SPECIALISING in Heavy Steel Structures, Project Shifting, Erection and Commissioning, Plant Maintenance, Steel Sheeting, Old Plant Maintenance & projects work for last 2 DECADES “OUR AIM 100% customer satisfaction with highest level of professional integrity.”

Siddhi Tech has a reputed list of prominent customers, eg. VVF Ltd at their plants at Sion , Taloja, Kutch Gujarat, Baddi in Himachal Pradesh, B. P Refineries, Allana Sons, GFTFH & Petcock Heaters.

Siddhi Tech has been associated with TANNOY PROJECT CONSULTANTS in projects in the steel plant of UMCL, Kafue, Zambia, ArcelorMittal’s Heavy Steel Fabrication unit in Ranipet, Tamilnadu, New Era Fabric’s Ware Housing Unit at Patalganga and now Eco Recycling e-scaping Plant at Vasai East

Mr. Kripa Kandade

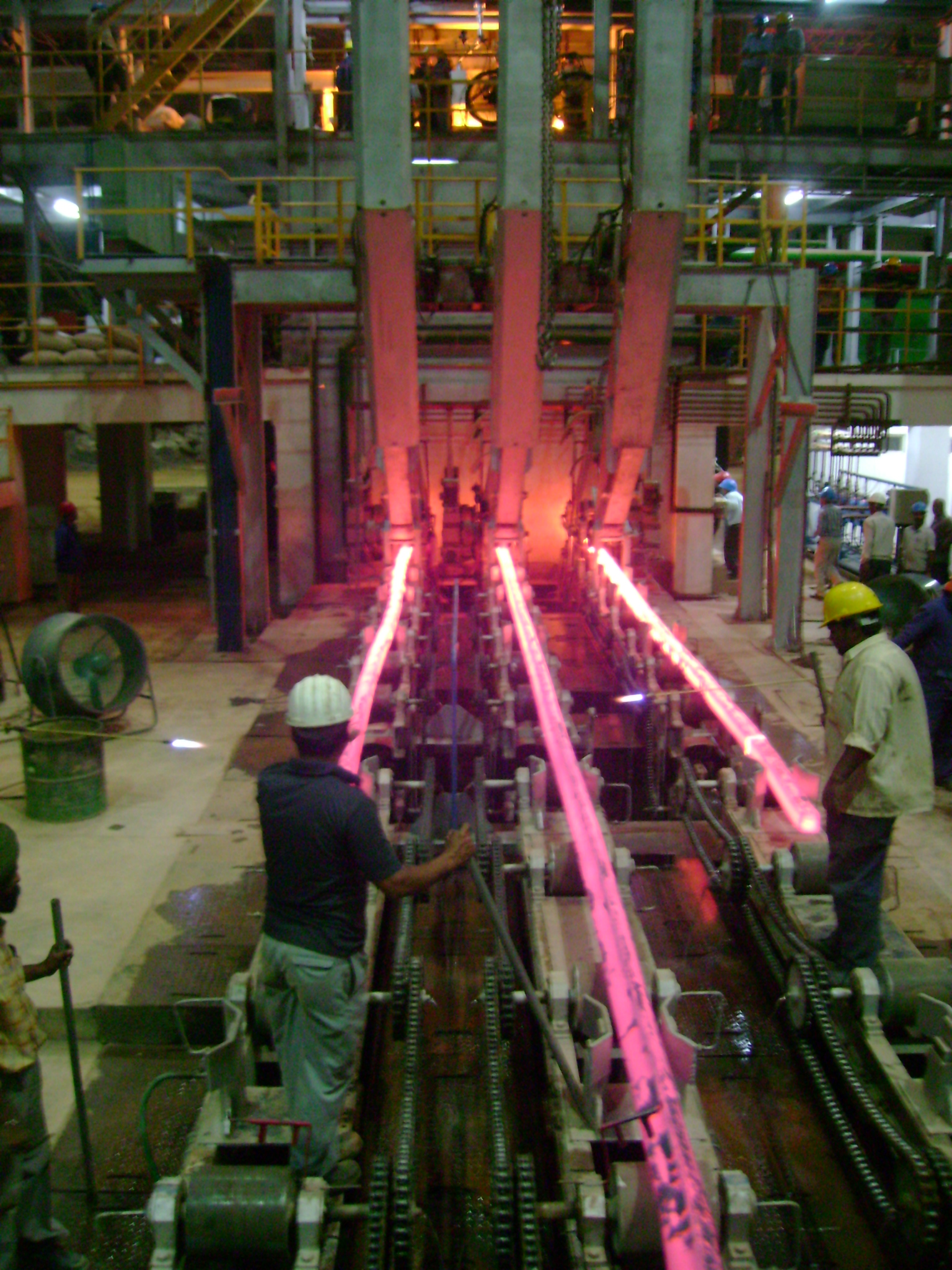

Fykay’s Engineering. Managing Director Kripa Kandade’s MAJOR FOCUS is on developing

Futuristic Designs for Systems of Combustion Control Solutions for ALL INDUSTRIAL

SITUATIONS WHERE COMBUSTION TAKES PLACE. Excellent Results have been

Realised of Savings in Metal SCALE LOSS in Metallurgical Systems as seen in the visual

in the steel re-heating and heat treat industry plus Fuel & Power Consumption. The system

is called Fykays TOPS, that is Temperature, Oxygen and Pressure. The system is

amenable for all FUELS.

Our systems also have applications in Cement, Refractory, Boiler Efficiency for Power

Plants, Sugar SOR BAGAS FUEL and Distilleries for ETHENOL.

PAYBACK PERIOD IS A MATTER OF DAYS.

Fykays Engineering specialises in all instrumentation for the Metals Industry for the past 5

decades.

S P Mishra

A dynamic professional with over 37 years of rich extensive experience in the field of Ferro AlloysSteel, Melting Rolling, positions held include R& D Officer, Production Manager, General Manager, Technical Director andVice President,CEO, in various Steel Plants & Rolling Mills and Ferroalloy plants across India.

Started Career from M/s. DandeliSteels and Ferro Alloys, North Karnataka, Karnataka,Aslo Steels Ltd, Panchmahal ,Gujarat; R B JodhamalJammu;M/S Kundil Group, GoaBadrinarayan Alloys and Steels Ltd UlubariaDist-Howrah, R.K.Ferro Alloys & Metals Pvt Ltd, and the M/S.Shah Alloys Ltd. as a CEO. Science Graduate from Gorakhpur University in 1978 with a Post .Graduate .Diploma in Metallurgical Chemistry University from V.J.T.I. Mumbai

Sikkander Amin

A Technocrat with a background of more than 30 years as a Technology & Project Consultant, he has successfully served as a technology advisor for several top MNCs and government organizations around the world. In 2010 he started Vigor Solar Energy Pvt Ltd and as an MD has since taken it to high growth and success through the last decade. He has successfully executedmore than 300 major Solar EPC projects on a pan India basis for companies like Tata Power, L&T, Gamesa, HatsunAgro, Philips, TTK Prestige, NIOT, BEL& Fortis Hospital to name a few. Pioneered the largest EPC rooftop solar project in South India, the first utility scale ground mounted wind solar hybrid plant in India and the first offshore solar plant in Lakshwadeep.He has been instrumental in successful design and implementation of several major solar projects for the government and defence sectors and has served as an advisor to the Niger government for their solar power and renewable energy strategies.Solar Panels and Windmill has also been installed in one project

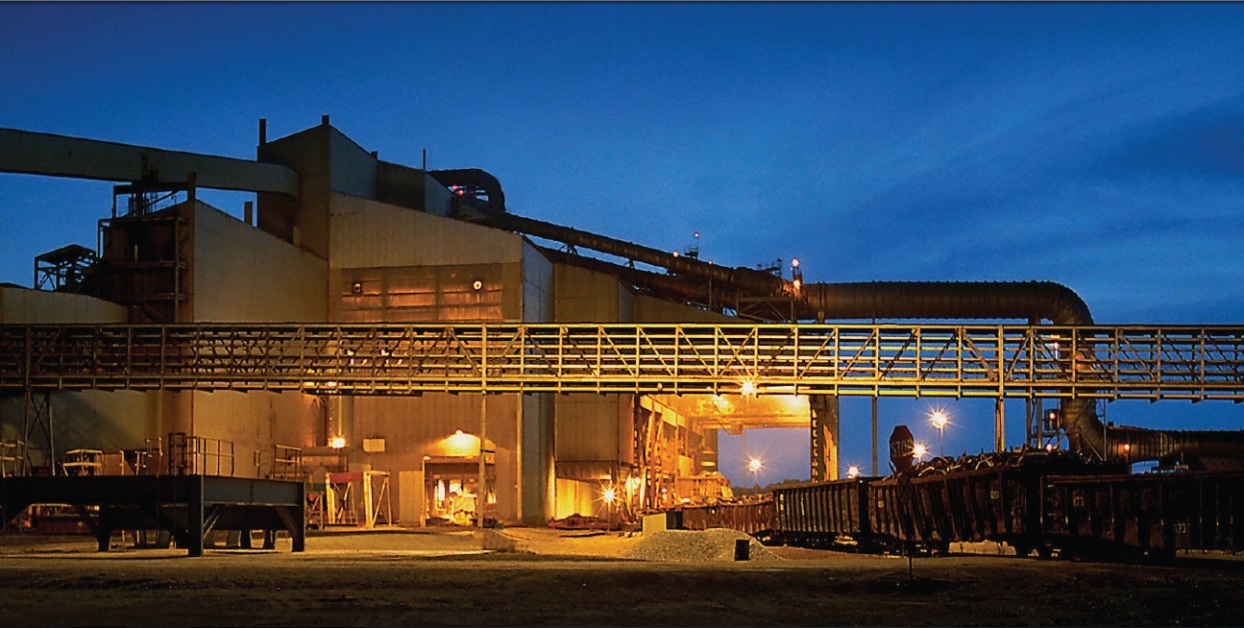

Your total solution provider for Steel. With extensive experience in executing EPC plants, Tannoy offers the largest breadth of solutions throughout the steel supply chain.

Your total solution provider for Steel. With extensive experience in executing EPC plants, Tannoy offers the largest breadth of solutions throughout the steel supply chain. Your total solution provider for Steel. With extensive experience in executing EPC plants, Tannoy offers the largest breadth of solutions throughout the steel supply chain.

Your total solution provider for Steel. With extensive experience in executing EPC plants, Tannoy offers the largest breadth of solutions throughout the steel supply chain.

Engineering, Procurement, Construction & Management Solutions (EPCM)

Engineering, Procurement, Construction & Management Solutions (EPCM) Building on Market and Geographic Diversity

Building on Market and Geographic Diversity